What is air bending?

Air bending is bending your material past the desired angle and allowing the part to springback to the desired angle. This takes less tonnage than bottom bending. Typically an air bending tool is designed with an additional 5 degrees more than desired angle. Check with Power Brake Dies for more press brake tooling details.

What is bottom bending?

Bottom bending dies are inherently more accurate than air bending dies. The punch and die are made to the desired angle. Clearance between punch and die is usually just equal to metal thickness. Minor variations in stock thickness are ironed out when the punch bottoms in the die. Check with Power Brake Dies for more press brake tooling details.

What is coining?

Coining occurs when a very sharp radius is required. The clearance between punch and die is reduced to less than material thickness. This causes some coining to occur at the bottom of the stroke. The stock is compressed and springback is reduced. This procedure should be used with extreme care. Tonnage requirements increase drastically and there is the hazard of spoiling the work, at best, or wreaking the press brake. Check with Power Brake Dies for more press brake tooling details.

What is an Acute Die?

An acute die is typically cut to 30 degrees. They are used in the first operation of hemming material. Standard acute die openings range from 1/4” to 1 ½”. Check with Power Brake Dies for more press brake tooling details.

What is an Acute Punch?

An acute punch works in conjunction with acute dies. They allow your material to be bent near 30 degrees. The stand radii on acute punches range from 1/32 radius to ⅛ inch radius. Check with Power Brake Dies for more press brake tooling details.

What is brake die steel?

Brake die steel is typically 4150 steel. It comes in bar stock lengths. It’s Rockwell hardness is 27- 30c. It can be flame hardened to 50-55 Rockwell-C for approximately 3/32 inch depth. Check with Power Brake Dies for more press brake tooling details.

Can tools be reworked?

In most cases tools can be reworked. Wear and tear on the working surface of the tools can be re-dress to a fresh working surface. In some cases brand new shapes can be cut into an old tool at substantial savings compared to a new tool. Talk to an engineer at Power Brake Dies for more press brake tooling details.

Should tools be polished?

When forming polished finished material, aluminum, stainless steel, or painted material, Power Brake Dies can offer a super fine polished working surface on your tools.

What are the American standard tongue dimensions?

Power Brake Dies follows the industry standard for American tongues. The width is .500/.490. The height is 5/8 inch. (See diagram below)

What are the standard American safety tongue dimensions?

Power Brake Dies follows the industry standard for American safety tongues. The width is .500/.490. The height is 3/4 inch tall The safety hook is 7/32 inch x 1/8 inch. (See diagram below)

What are Gooseneck Punches?

Gooseneck Punches are for forming channel shapes in two strokes or for forming special shapes where a straight punch would interfere. Check out the family of Gooseneck punches offered by Power Brake Dies.

What are Flattening Dies?

Flattening dies are used to complete a hem or close a given degree of opening a previously formed acute angle. Talk to an engineer at Power Brake Dies for any press brake tooling questions.

What are Offset Dies?

Offset dies are designed to form two bends with one stroke. The measurement is needed as the in-to-out dimension from one plane to another. Talk to an engineer at Power Brake Dies to discuss application and required tonnages.

What are 85 degree Punch and Dies?

85 Degree Punch and Dies are typically used to produce 90 degree bends in heavy gauge or plate. Most forming in this category is air forming to keep machine capacities to a minimum and prevent material fracture. Power Brake Dies offers an entire family of 85 degree dies.

Are DXF files available?

Yes. Upon request, DXF files of any standard tool or your purchased special designed tool will be available from Power Brake Dies.

What are the tool dimensions?

All dimensions listed in our literature or website are nominal and subject to minor changes. Thus the overall widths represent the thickness of the bar stock before being cleaned up. Dies can be of any length, but typically run in 2 foot increments. Dimensions are subject to change without notice. Be sure to check with the engineering team at Power Brake Dies for more press brake tooling information.

How is a die Vee-opening measured?

It depends on the type of lower die. An acute die is measured from center radius to center radius. A 90 or 85 degree die is measured from the theoretical intersection to theoretical intersection. Talk to an engineer at Power Brake Dies for more press brake tooling details.

What is a tool's net height?

On a punch it is from the tools shoulders down to the tip of its radius. (Does not include the tools tongue) On a die it is from the tools base up to the top of the die (does not include tools tongue). Check with Power Brake Dies for more press brake tooling details.

What is meant by “Clean Up” dimension?

Clean Up dimension is the width of the tools as raw bars. The sides of the bar are cleaned up to remove the scale and raw material. The bar loses approximately 1/16 inch per side. A clean up to 2 inch would finish approx. 1 ⅞ inch. Contact us at Power Brake Dies for more press brake tooling details.

Are DWG files available?

Yes. Upon request, DWG files of any standard tool or your purchased special designed tool will be available from Power Brake Dies.

Are PDF files available?

Yes. Upon request, PDF files of any standard tool or your purchased special designed tool will be available from Power Brake Dies.

What are Flattening Dies?

Flattening dies are used to complete a hem or close to a given degree of opening a previously formed acute angle. Talk to an engineer at Power Brake Dies for more press brake tooling details.

Power Brake Dies follows the industry standard for American safety tongues. The width is .500/.490. The height is 3/4 inch tall The safety hook is 7/32 inch x 1/8 inch.

Safety Tongue Dimensions

Power Brake Dies follows the industry standard for American tongues. The width is .500/.490. The height is 5/8 inch.

Standard Tongue Dimensions

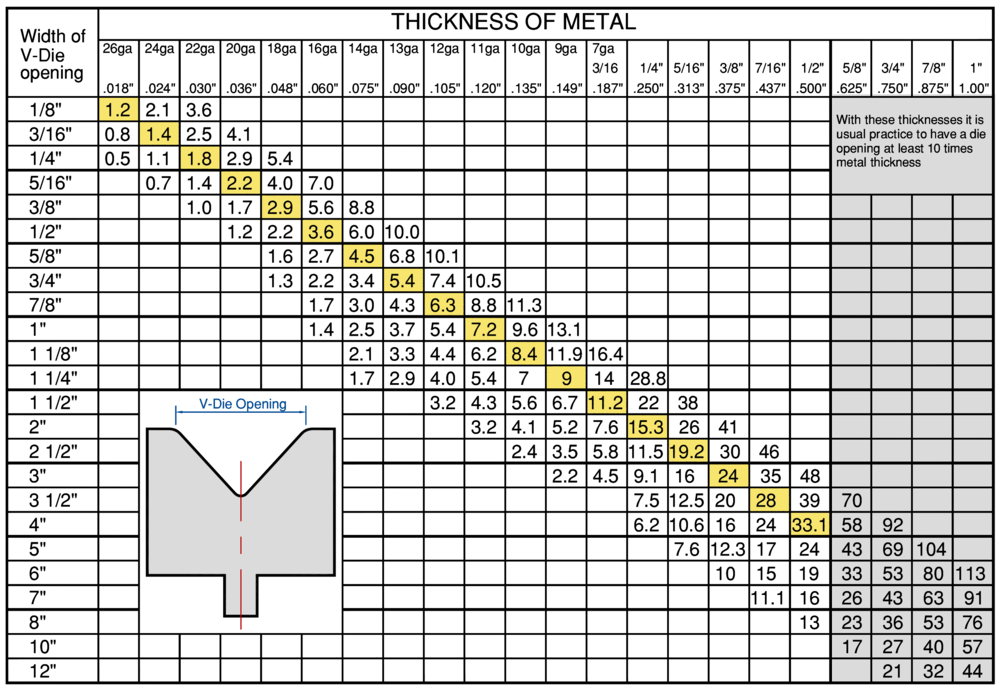

Press Brake Tooling Tonnage Chart

APPROXIMATE PRESSURE IN TONS PER LINEAR FOOT REQUIRED TO MAKE 90-DEGREE AIR BENDS ON MILD STEEL

Figures within the yellow areas are the tonnage required using a punch with a radius equal to the metal thickness and die opening approximately eight times metal thickness. This combination produces an air bend with an inside radius nearly equal to metal thickness. A good practical minimum for 90-degree bends.