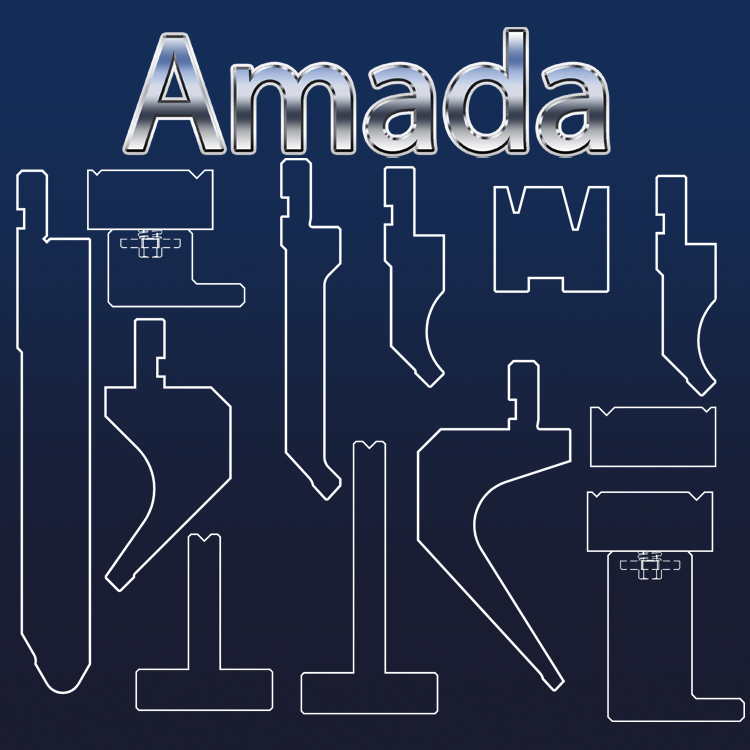

Amada Precision Ground Tooling

Our Precision Ground European line of tooling is interchangeable with many popular European/Amada style tooling.

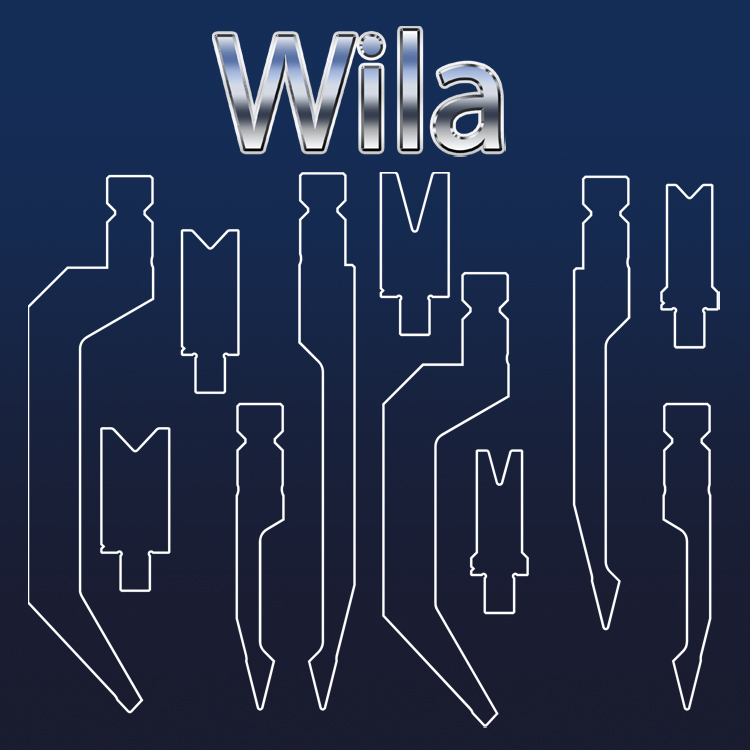

Wila Precision Ground Tooling

Our line of Wila style tooling is manufactured to be interchangeable with many Wila Standards.

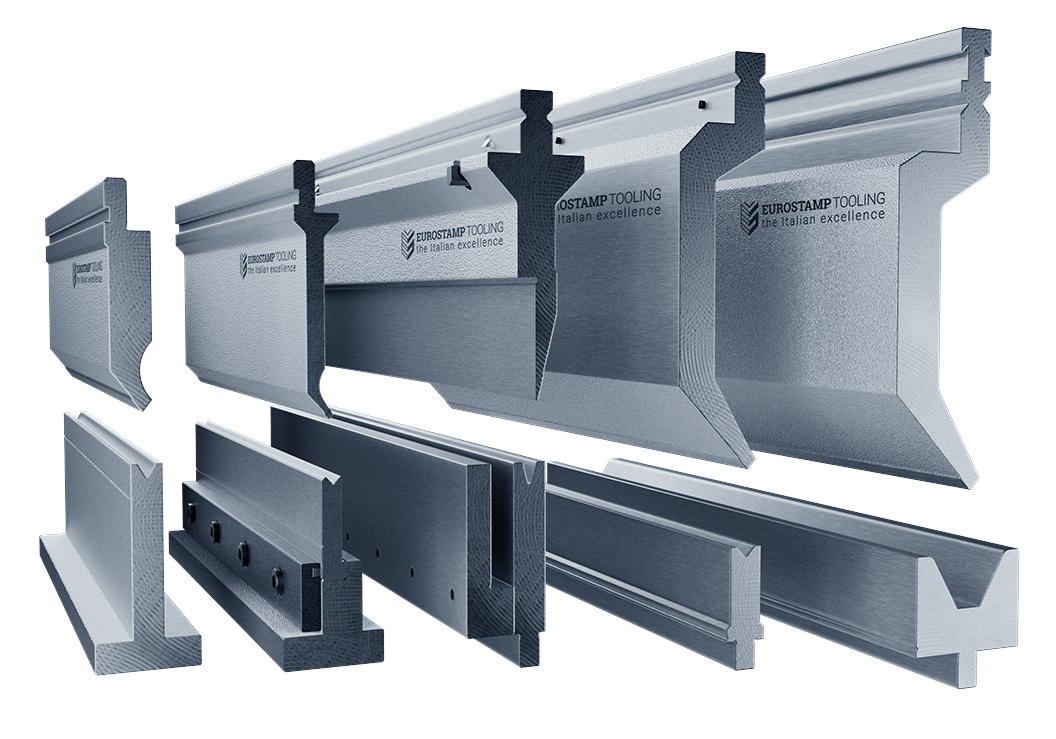

Special Tooling

Our line of special tooling. These can be made with American, Wila or European Tangs.